Contact Us

13922298476(Mr. Huang)

020-32039131, 32030604

Address: 2514-2516, building T1, Vanke center, No. 1080, Huangpu East Road, Huangpu District, Guangzhou

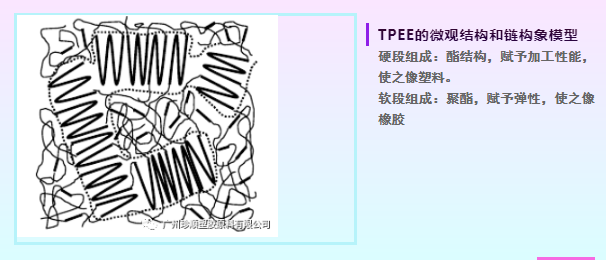

【Zhenshun Plastic】Introduction of TPEE materials

【Zhenshun Plastic】Introduction of TPEE materials

- Categories:Industry knowledge

- Author:Xiao Cheng

- Origin:

- Time of issue:2021-01-12 15:32

- Views:

(Summary description)TPEE has the elasticity of rubber and the strength of engineering plastics. Compared with rubber, it has better processing performance and longer service life; compared with engineering plastics, it also has the characteristics of high strength, flexibility and dynamic mechanical properties. better.

【Zhenshun Plastic】Introduction of TPEE materials

(Summary description)TPEE has the elasticity of rubber and the strength of engineering plastics. Compared with rubber, it has better processing performance and longer service life; compared with engineering plastics, it also has the characteristics of high strength, flexibility and dynamic mechanical properties. better.

- Categories:Industry knowledge

- Author:Xiao Cheng

- Origin:

- Time of issue:2021-01-12 15:32

- Views:

TPEE has the elasticity of rubber and the strength of engineering plastics. Compared with rubber, it has better processing performance and longer service life; compared with engineering plastics, it also has the characteristics of high strength, flexibility and dynamic mechanical properties. better.

1. Features of TPEE

1. Good creep resistance, impact resistance and fatigue resistance

2. High impact strength and good low temperature flexibility

3. Maintain good performance when the temperature rises

4. Good resistance to chemicals, oils, solvents and weather

5. High tear strength and high abrasion resistance

6. Easy to process and economical

7. Good recyclability

2. TPEE processing technology

Process: welding → drying → heat treatment → rheology → molding (injection, extrusion, rotomolding, casting melting, extrusion blow molding) → mechanical processing → recycling

Welding method: hot air, reflector, heating element and high frequency, ultrasonic welding, spin welding

Drying conditions: 107℃, incubator with air desiccant for 2~3h, and incubator without air desiccant for 4~6h

Rheology: The viscosity depends on the temperature, and higher torque and injection pressure are used when molding the harder grades.

Injection molding: generally used for polyethylene molding equipment, molding temperature 260~270℃, mold temperature 4~65℃

Blow molded parts: film, sliding-casting molded parts

Rotomolding: powder rotomolding

Extrusion blow molding: the thickness is reduced to 20μm, the maximum inflation coefficient is 2.8

Recycling: Grind the materials, dry the materials, do not need to be annealed, and can be blended with the new materials at a ratio of 25% to 50%, and the flow rate of the single material melt cannot be reduced.

3. Application of TPEE

1

Scan the QR code to read on your phone

Contact

13922298476(Mr. Huang)

Address: 2514-2516, building T1, Vanke center, No. 1080, Huangpu East Road, Huangpu District, Guangzhou

Copyright © 2021Guangzhou Zhenshun plastic material Co., Ltd Powered by:www.300.cn guangzhou.300.cn 粤ICP备20004324号